PRODUCT & SERVICES

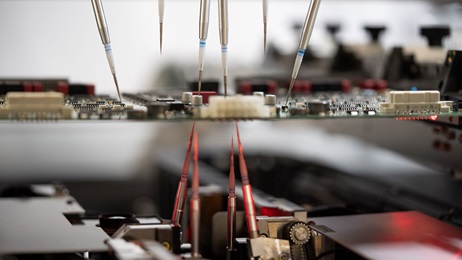

Flying Probe Tester

In 1978, we developed the world's first flying probe tester and continue to hold a top-tier global market share. Our solutions are adopted by major companies worldwide—in semiconductors, automotive, aerospace, medical devices, and more—contributing to the prevention of PCB assembly defects. By designing and manufacturing in-house, we deliver high quality and flexible customization.

- What is an in-circuit tester?

- Lineup

- Partner

What is an in-circuit tester?

This is an inspection device that electrically detects defects in printed circuit board assembly.

Lineup

We offer a comprehensive lineup capable of meeting all testing needs, including high-speed, high-precision testing, double-sided testing, support for large, heavy boards, and special custom solutions.

RFID

With over 25 years of experience in RFID equipment, we are RFID professionals who support your operational efficiency with extensive implementation experience and technical expertise. We respond to diverse on-site needs with flexible product proposals tailored to your challenges.

- Search by hardware

- Search by Software

- Contract Development

Search by hardware

HF Band

The HF band (13.56 MHz) is an electromagnetic induction-based RFID system. Known as proximity-type or close-range type, it is suitable for use at communication distances of 0 to 70 cm.

UHF band

The UHF band (920 MHz) operates using radio frequency (RFID) technology. It enables communication over distances of several meters or more. Output settings can also be adjusted for use at close range.

LF band

The LF band (134.2 kHz) is an electromagnetic induction-based RFID system. It is widely used for applications such as livestock and pet identification, as well as in semiconductor factories.

Search by software

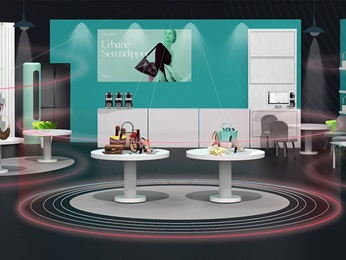

Store Security

We safeguard facility security with diverse security products, including EAS gates and various self-alarming tags. We handle the core system components—PCB design and software development—in-house, while also providing integrated production for EAS systems, from PCB design to assembly.

- Products

IT Solution

We provide comprehensive support—from planning and proposal to implementation and operation—for solutions that leverage optimal IT to address challenges faced by businesses, such as improving operational efficiency, reducing costs, and enhancing competitiveness.

- SI

- Plex/2E

SI

Drawing on our proven track record and expertise cultivated across diverse industries and sectors, we provide comprehensive support from upstream processes—including business analysis, issue identification, and improvement proposals—through to design, development, and implementation. We propose optimal solutions tailored to your needs, delivering reliable technology and hands-on support to help you achieve operational efficiency, cost reduction, and enhanced competitiveness.

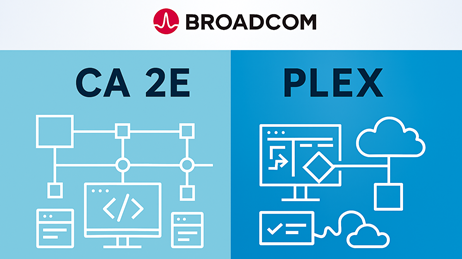

Plex/2E

We provide specialized training programs and development support services focused on CA Plex, an architecture-based RAD tool, and CA 2E (formerly Synon), a model-based rapid application development tool. Leveraging our extensive experience and expertise, we comprehensively support our customers' development infrastructure from implementation through training, deployment, and maintenance.

DX

We provide comprehensive support, from building systems that leverage corporate data to visualize operations on the ground, to enabling management decisions based on that data. From strategy formulation, KPI design, and dashboard construction to continuous improvement proposals, we partner with you from a practical perspective. This bridges management and the field, enabling us to challenge ourselves alongside our clients to create new business models.

- Working closely with the field to create new added value

- Takaya IoT Platform Service

Working closely with the field to create new added value

We deeply understand on-site operations, identify challenges together, and collaborate to devise solutions. Through business process visualization, system design, data utilization, and automation, we create new value rooted in the field by leveraging cloud services. We walk alongside the field not just through “implementation,” but all the way to “sustained results and evolution.”

Takaya IoT Platform Service

Our cloud service enables data collection and storage from RFID devices, along with visualization of the collected data. Read IC tag data is transmitted to the cloud for storage and can be visualized using standard dashboard functions. Furthermore, API access allows direct access to the data storage.

EMS

Our integrated production system combines cutting-edge equipment with automation technology to provide a one-stop solution covering everything from design and parts procurement to surface mount technology (SMT), PCB processing, and assembly. We cater to a wide range of industries and needs, including home appliances, industrial equipment, automotive, and medical fields. Through engineering services such as automation planning and process design, we advance manufacturing to the next level.

- Takaya's EMS

- Service Flow

- Optimal Production Sites

- Certifications

- Customer Categories

Takaya's EMS

From design and PCB assembly to prototyping, production, and maintenance, we offer full support. We respond to various outsourcing needs, such as design and production consignment from customers.

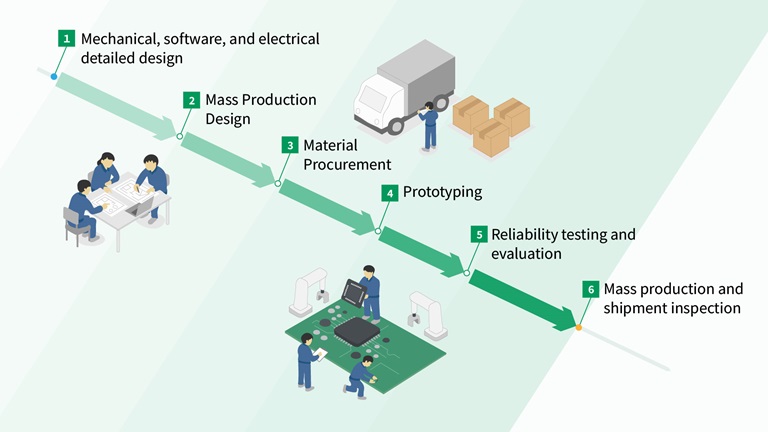

Service Flow

In each service flow, we combine our technical expertise with many years of manufacturing experience to provide high-quality services.

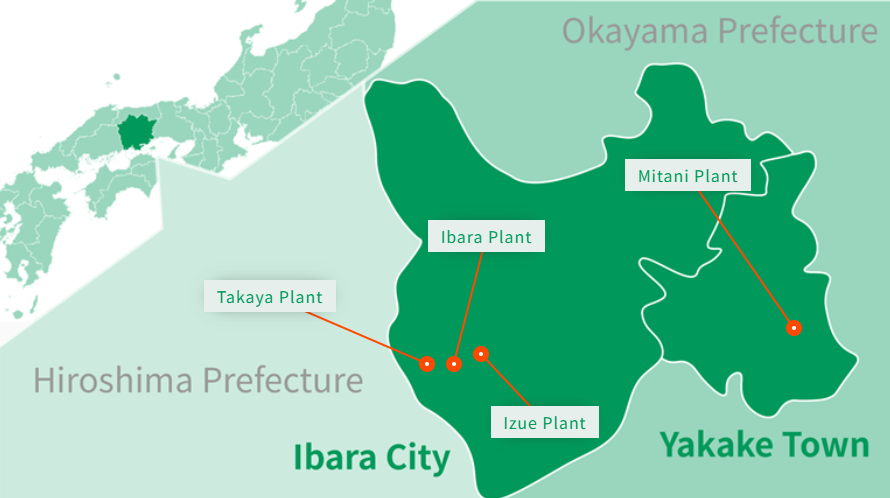

Optimal Production Sites

EMS production in China and Thailand. (China: 10 SMT assembly lines / Thailand: 8 SMT assembly lines) As of August 2025 — We achieve mass production at overseas bases through domestic prototyping and parts procurement.

Certifications

We have established an integrated management system certified for ISO9001, ISO14001, and IATF16949.