EMS

Electronic Manufacturing Services

Crafting Innovation

for a Future Beyond

We offer optimal solutions with excellent cost performance to meet a wide range of customer needs — from short lead times and small-lot production to mass manufacturing.

Takaya’s EMS

A comprehensive production system that delivers high quality, short lead times, and low costs

We provide full support from design and PCB assembly to prototyping, production, and maintenance. We also handle design and manufacturing outsourcing to meet diverse customer needs.

Proposals for the Optimal PCB Assembly System

We have introduced state-of-the-art Panasonic dual lines and FUJI lines to promote automation and labor-saving in SMT processes. We offer optimal production systems to meet the needs of various customers — from automotive and industrial equipment manufacturers to others — covering everything from high-mix small-lot to mass production.

Achieving Optimal QCD through Proprietary Expertise

With 40 SMD towers (reel component storage units) connected to our production execution system through a proprietary interface, we achieve automatic dispensing of reel materials according to production plans. This significantly reduces changeover time and ensures stable QCD for our customers.

Takaya Engineering Services

In addition to promoting digital transformation (DX) within our processes in collaboration with our IT division, our engineers have realized automation and labor-saving through collaborative robots and automated conveyance systems.

We offer a variety of engineering services related to EMS, including the design and production of checkers and jigs.

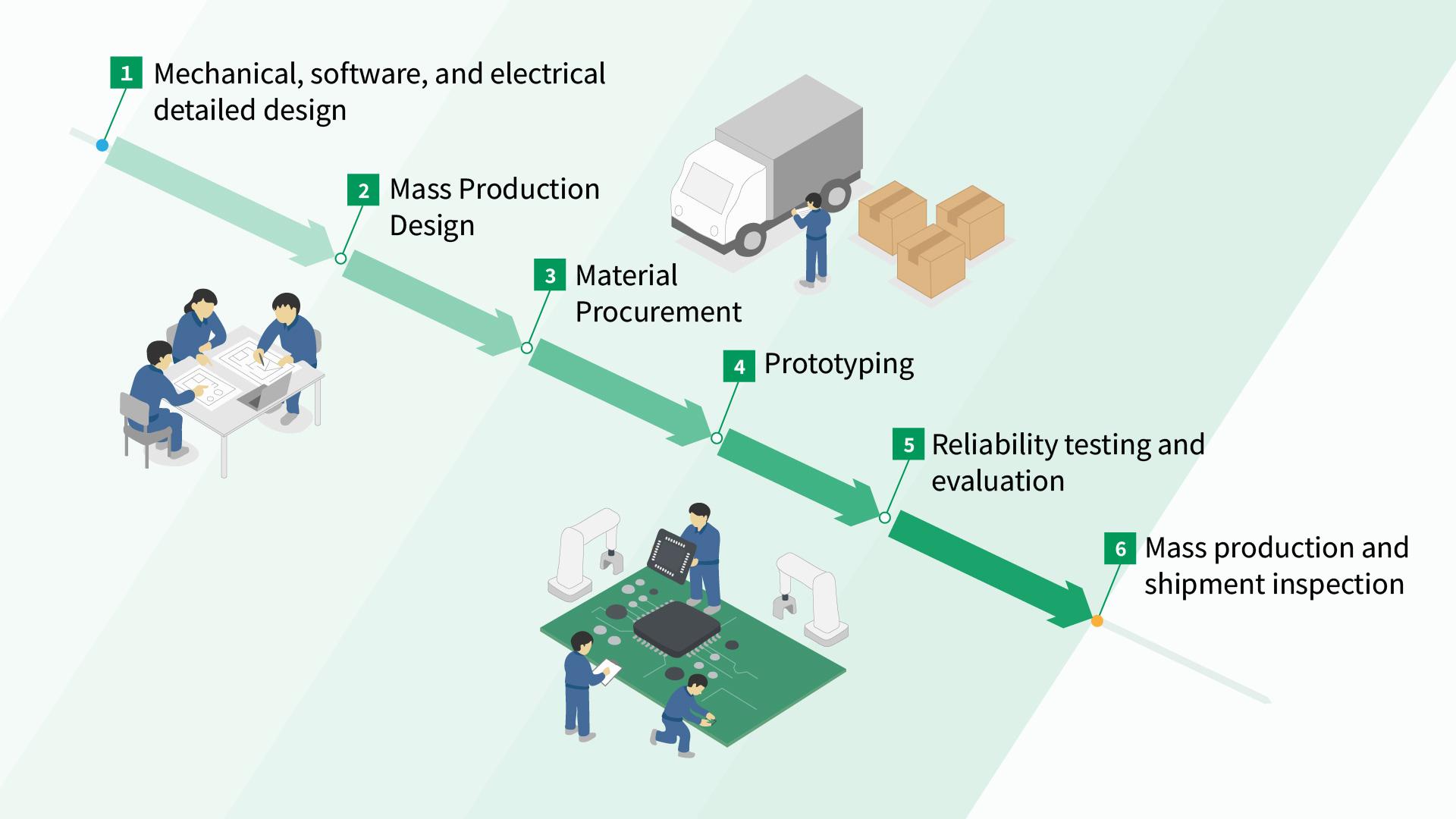

A system combining expertise in each service flow with decades of accumulated manufacturing experience

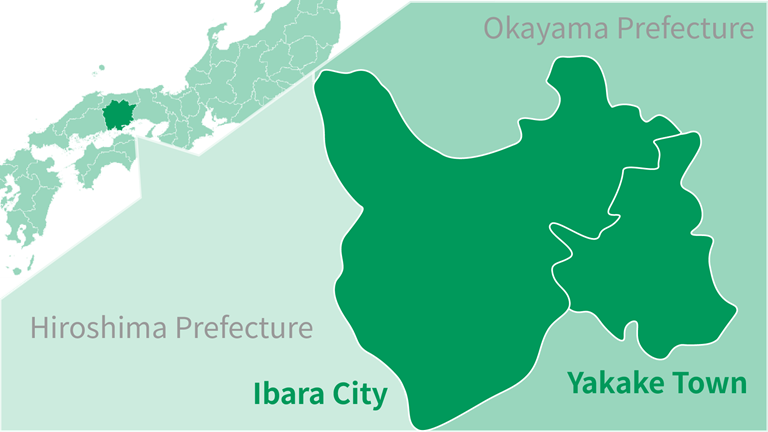

Optimal Production Locations (Japan, China, Thailand)

EMS production in China and Thailand (China: 10 SMT lines, Thailand: 8 SMT lines as of August 2025). We achieve mass production at overseas sites through domestic prototyping and component sourcing.

Production Sites: Japan

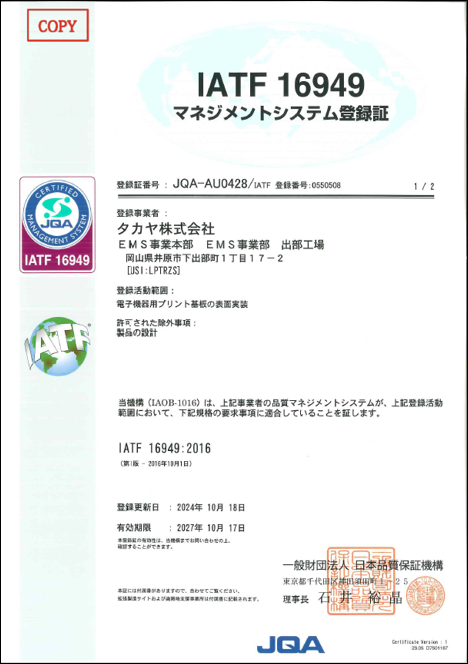

Implementation of an Integrated Management System Certified under ISO 9001, 14001, and IATF 16949

ISO9001

ISO14001

IATF16949

Customer Categories

Industrial Equipment

Consumer Electronics

Medical Equipment

Automotive Equipment